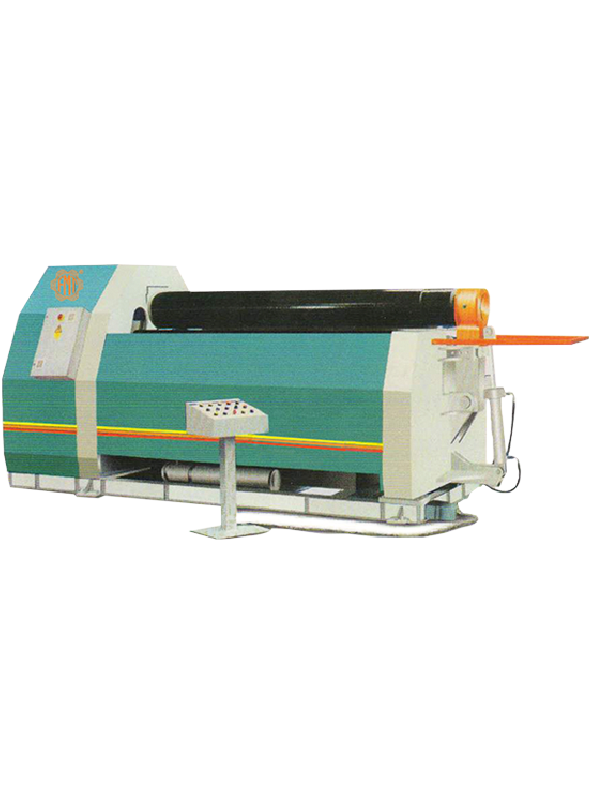

Easy to maintain and useful for various jobs. Modern design and rigid structure. So simple mechanism that even semi-skilled worker can do accurate job. Very useful for g etting Cylindrical shapes and better performance. It works with 3 Rolls pyramid principal. Bottom rolls are fixed and driven by Gears and warm Reduction Gear Box. Top roll rotates in fixed position and can be adjusted up & down manually by adjustable screws, in mechanical version and by Hydraulic system & cylinder In Hydro mechanical version.

Housing is made from M. S. plate of suitable strength and mounted on heavy base frame, Rolls are made from forged steel and perfectly machined for accurate results. For correct feeding and grip, axial grooves are provided on bottom rolls. A screw jack/extra Hydraulic cylinder is given to keep the top roll horizontal when the formed shell is to take out.

Our machines are fitted with Electric Brake Motor and Movable Control Panel, so that machine can be stopped at any stage of operation, hence the shape in rolling as per requirement is most possible and due to the movable control panel machine can be operated very easily.

The Plate Bending Machine is fitted with a total of 2 nos. Gear Box, Electric Brake Motor, Push Button Type Movable operating switchboard and Electric control panel for easy & safe operation.

We only offer the machine with double Gearbox, one is a warm Gearbox and another is a spur reduction gearbox, due to this, the fatigue in operation and overload on the electric motor and warm reduction Gear box is totally avoided even when the machine is Working in overcapacity and more over bending operation becomes easier.

Plate Bending Machine is made out of quality prime materials.

Only Top Roll Pressing (Up-Down) and opening and closing of the drop end are through the hydraulic system & cylinders all other operations are carried out mechanically in a hydro-mechanical version. In the mechanical version Top Roll Pressing is done manually by means of screws and the opening/closing of the end-dropper is manual or motorized.

Hydro-Mechanical machines required less manpower compared to the mechanical versions, and the same directly affects your production rate and finish job value.

Apart from the above the rates are more competitive in their range.

STEP OF BENDING OPRATIONS

- The plate can be Bent on machine by hammering as shown if the thickness of the plate is half than rated capacity. Thicker plates should be prebent out side the machine.

- Place the plate between bottom and top rolls by adjusting top roll manually/hydraucally.

- Down the top roll and give pressure on the plate. Then start main motor in clock wise direction till one end of the plate comes over first bottom roll reverse the motors and get second end on second bottom.

- Continue above process until you get desired shall as shown in picture.

| MODEL NO. | CAPACITY MM. | ROLL DIA.MM. | MAIN DRIVE H.P. | END. DROPER H.P |

|---|---|---|---|---|

| FPB 10:04 | 1000 X 4 MM | 110/105 | 3.00 | MANUAL |

| FPB 12:04 | 1270 X 4 MM | 120/110 | 3.00 | MANUAL |

| FPB 15:04 | 1525 X 4 MM | 130/115 | 5.00 | 0.75 |

| FPB 20:04 | 2030 X 4 MM | 140/120 | 5.00 | 1.00 |

| FPB 25:04 | 2540 X 4 MM | 175/150 | 7.50 | 1.00 |

| FPB 30:04 | 3125 X 4 MM | 185/155 | 7.50 | 1 |

| FPB 10:06 | 1000 X 6 MM | 135/110 | 3.00 | 0.75 |

| FPB 12:06 | 12700 6 MM | 140/115 | 3.00 | 0.75 |

| FPB 15:06 | 1525 X 6 MM | 165/140 | 5.00 | 1.00 |

| FPB 20:06 | 1270 X 6 MM | 175/145 | 7.50 | 1.00 |

| FPB 25:06 | 2540 X 6 MM | 190/160 | 10.00 | 1.50 |

| FPB 30:06 | 3125 X 6 MM | 225/185 | 10.00 | 1.50 |

| FPB 12:10 | 1270 X 10 MM | 165/140 | 5.00 | 1.00 |

| FPB 15:10 | 1525 X 10 MM | 175/145 | 7.50 | 1.00 |

| FPB 20:10 | 2030 X 10 MM | 200/160 | 10.00 | 1.50 |

| FPB 25:10 | 2540 X 10 MM | 225/170 | 10.00 | 1.50 |

| FPB 30:10 | 3125 X 12 MM | 250/230 | 20.00 | 1.50 |

| FPB 12:12 | 1270 X 12 MM | 190/145 | 7.50 | 1.00 |

| FPB 15:12 | 1525 X 12 MM | 190/160 | 10.00 | 1.00 |

| FPB 20:12 | 2030 X 12 MM | 220/175 | 10.00 | 1.50 |

| FPB 25:12 | 2540 X 12 MM | 245/185 | 15.00 | 1.50 |

| FPB 30:12 | 3125 X 12 MM | 265/230 | 20.00 | 1.5 |

| FPB 12:16 | 1270 X 16 MM | 210/170 | 10.00 | 1.00 |

| FPB 15:16 | 1525 X 16 MM | 225/175 | 10.00 | 1.00 |

| FPB 20:16 | 2030 X 16 MM | 235/185 | 10.00 | 1.50 |

| FPB 25:16 | 2540 X 16 MM | 255/215 | 20.00 | 2.00 |

| FPB 30:16 | 3125 X 16 MM | 295/225 | 25.00 | 2.00 |

| FPB 12:20 | 1270 X 20 MM | 225/175 | 10.00 | 1.50 |

| FPB 15:20 | 1525 X 20 MM | 245/195 | 12.50 | 1.50 |

| FPB 20:20 | 2030 X 20 MM | 265/225 | 15.00 | 2.00 |

| FPB 25:20 | 2540 X 20 MM | 280/220 | 20.00 | 3.00 |

| FPB 30:20 | 3125 X 20 MM | 295/255 | 25.00 | 3.00 |

| FPB 12:25 | 1270 X 25 MM | 265/225 | 15.00 | 1.50 |

| FPB 15:25 | 1525 X 25 MM | 280/235 | 20.00 | 1.50 |

| FPB 20:25 | 2030 X 25 MM | 295/255 | 20.00 | 2.00 |

| FPB 25:25 | 2540 X 25 MM | 315/265 | 30.00 | 3.00 |

| FPB 30:25 | 3125 X 25 MM | 335/280 | 40.00 | 3.00 |

| FPB 12:30 | 1270 X 30 MM | 285/225 | 15.00 | 1.50 |

| FPB 15:30 | 1525 X 30 MM | 295/235 | 20.00 | 2.00 |

| FPB 20:30 | 2030 X 30 MM | 325/255 | 25.00 | 2.00 |

| FPB 25:30 | 2540 X 30 MM | 355/265 | 30.00 | 3.00 |

| FPB 30:30 | 3125 X 30 MM | 365/335 | 40.00 | 3.00 |

NOTE:

- All the capacity stated above is related to MILD STEEL of 42 kg. /MM2

- MAX. The cone Bending capacity possible is 70% of the pre-bending thickness.

- + / – 4% tolerance on all roll diameters.

- All dimensions are in MM

- Capacities not mentioned above are available on request & demand.

- We reserve the right to modify the design. The system, construction, dimension, weight, HP, Hydraulic Tonnage and other specifications of our machine without any prior notice for better performance of the machine.