- AN ISO 9001:2008 CERTIFIED COMPANY

- +91 94282 01789

- [email protected]

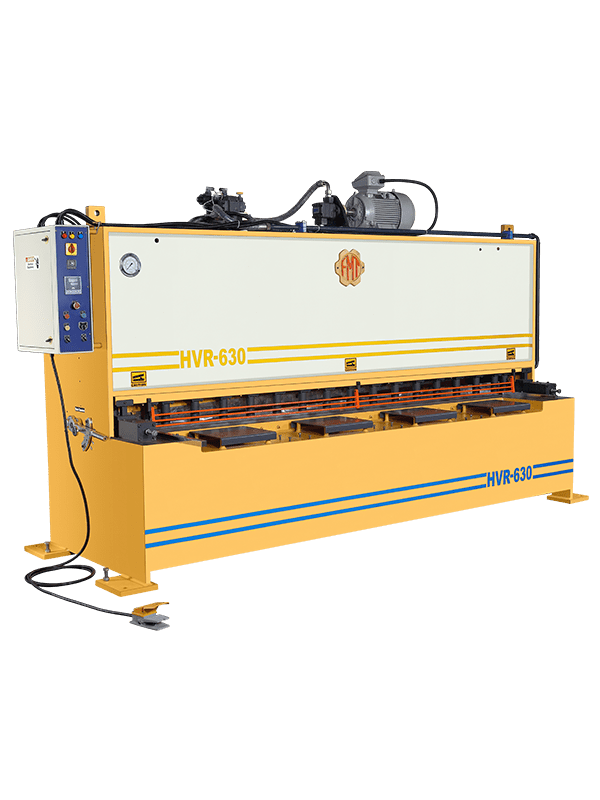

Hydraulic Shearing Machine

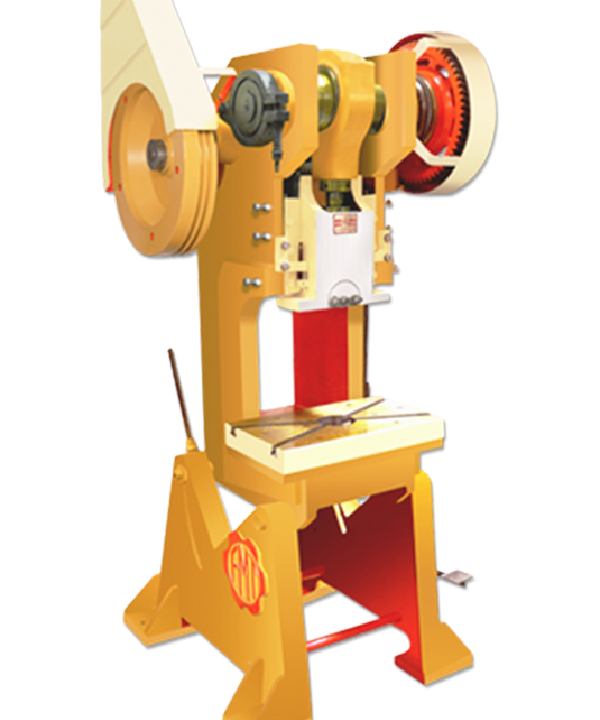

What is a Hydraulic Press & It’s Application And Uses

September 23, 2021

What is a Press Brake & It’s Types

September 29, 2021Generally, a shearing machine is a particular shear for press equipment with rotating discs and blades. Which is utilized for cutting metal sheets and bars. There are two types of divide cutting machines. linear and circular. Linear shears are developed for cutting metal over the thickness of 2 mm and are controlled hydraulically.

What is a Hydraulic Shearing machine?

Hydraulic shears are generally compact machines and it requires less space even though they apply the same type of pressure as mechanical shearing machines. Hydraulic shearing machines protect metal pieces with cramps while cutting metal so they ensure flawless cuts even for 90 degrees cuts.

Hydraulic shearing machine working

The hydraulic shearing machine system majorly maintains the pressure of the system and hydraulic oil’s direction. The press cylinder is utilized to manage the tool holder to recognize the shearing features. The presser foot majorly presses the metal workpiece to guarantee the workpiece’s precision.

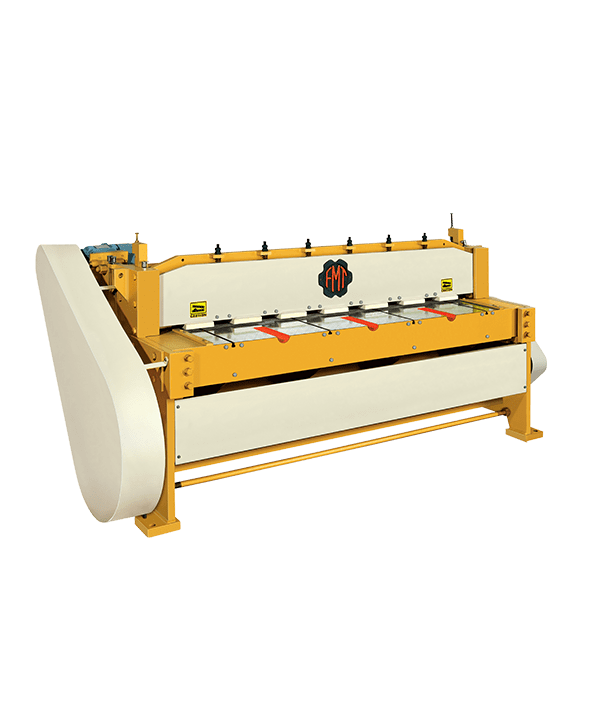

Utilization of Hydraulic shearing machine

Shearing machines are multifunctional devices, which are utilized in the cutting of alloys, other sheet metal. Such shearing machines utilize a scissor-like precise shear function to cut metal into sheets or strips.

Read also: Hydraulic Press Applications and uses

Process of shearing

Shearing is also popular as die-cutting. It is a process that cuts stock without the formation of chips or the utilization of melting. If the cutting blades are straight, then the process is called shearing. If the blades of cutting are curved then the process is called shearing-type operations.

Sheet metal shearing operations:

Shearing operations is the process of dividing the sheet metal into two or more pieces by cutting along a line. Generally utilized for cutting into rectangular shapes but can return other parts with different shapes also.